Process flow sheets Sugar from sugar cane Production process with flowsheet

A scheme showing the water flows in a sugar process production is appeared in Fig. 1. During the sugar pro- duction water flow in mill is appeared in Fig. 1 and water leaving the mill in following.

Process flow diagram of sugar processing Download Scientific Diagram

Knowledge in sugar industry technologies | capacity & EDD calculation with online calculators. we invite articles from all sugar technologists.. Raw Sugar Making Process with Flow Chart and specifications 21 Mar / 8 / siva alluri. Chemical Oxygen Demand (COD): Meaning, Applications, and Control Strategies.

Process flowcharts Sugar Products & Services Sucden

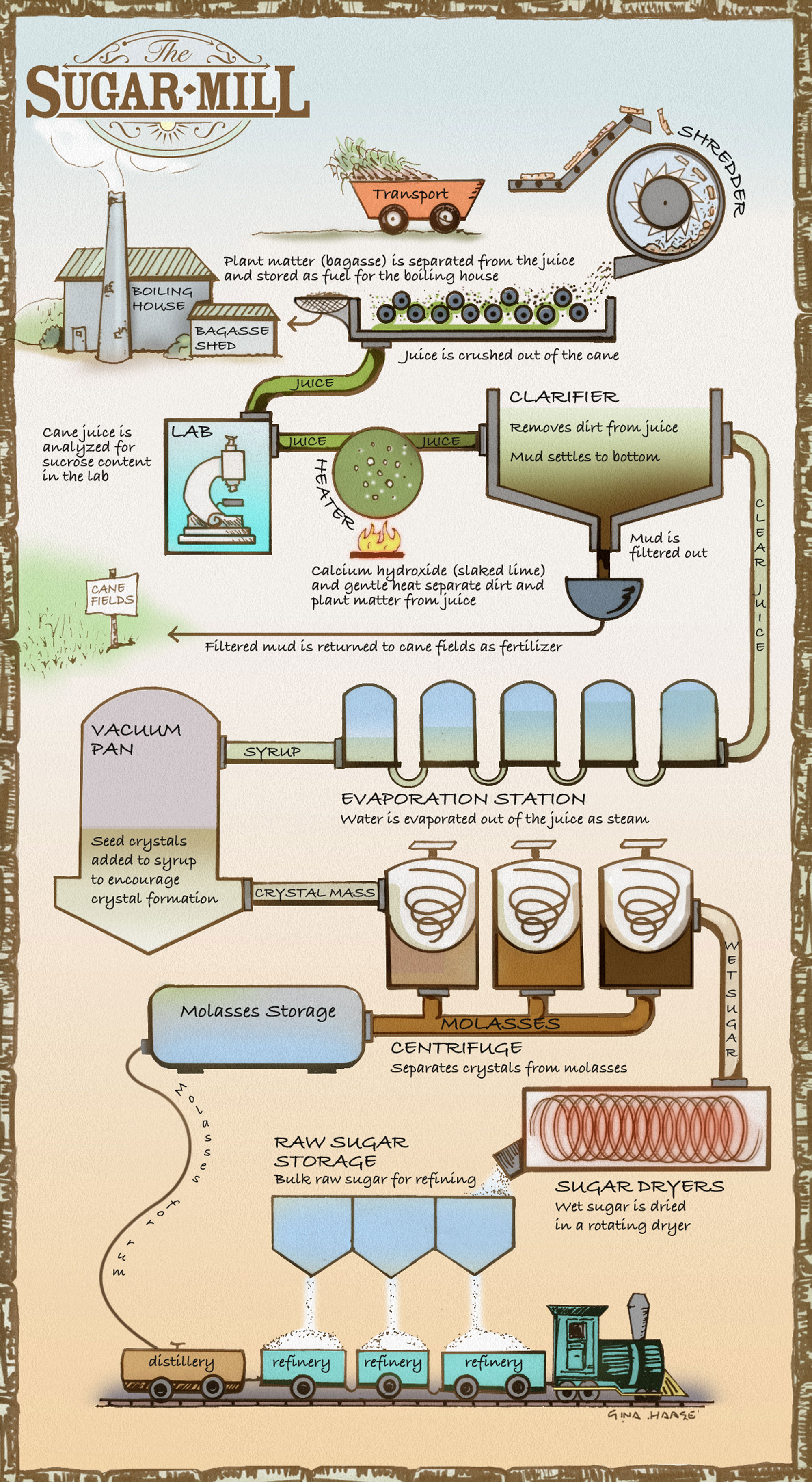

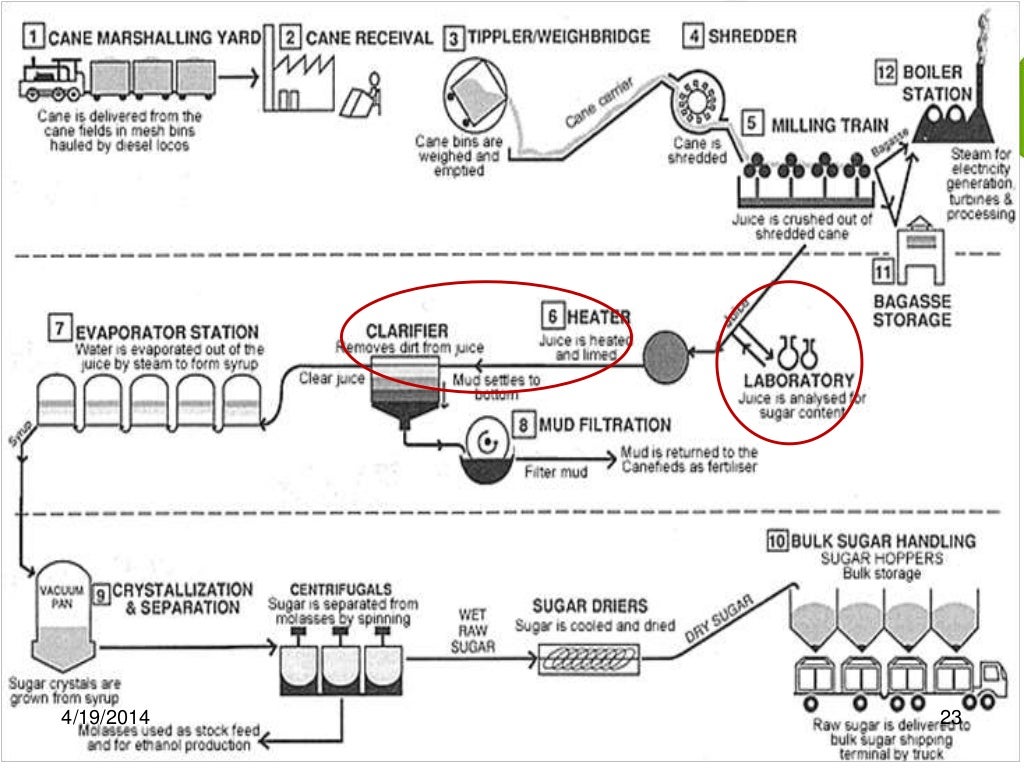

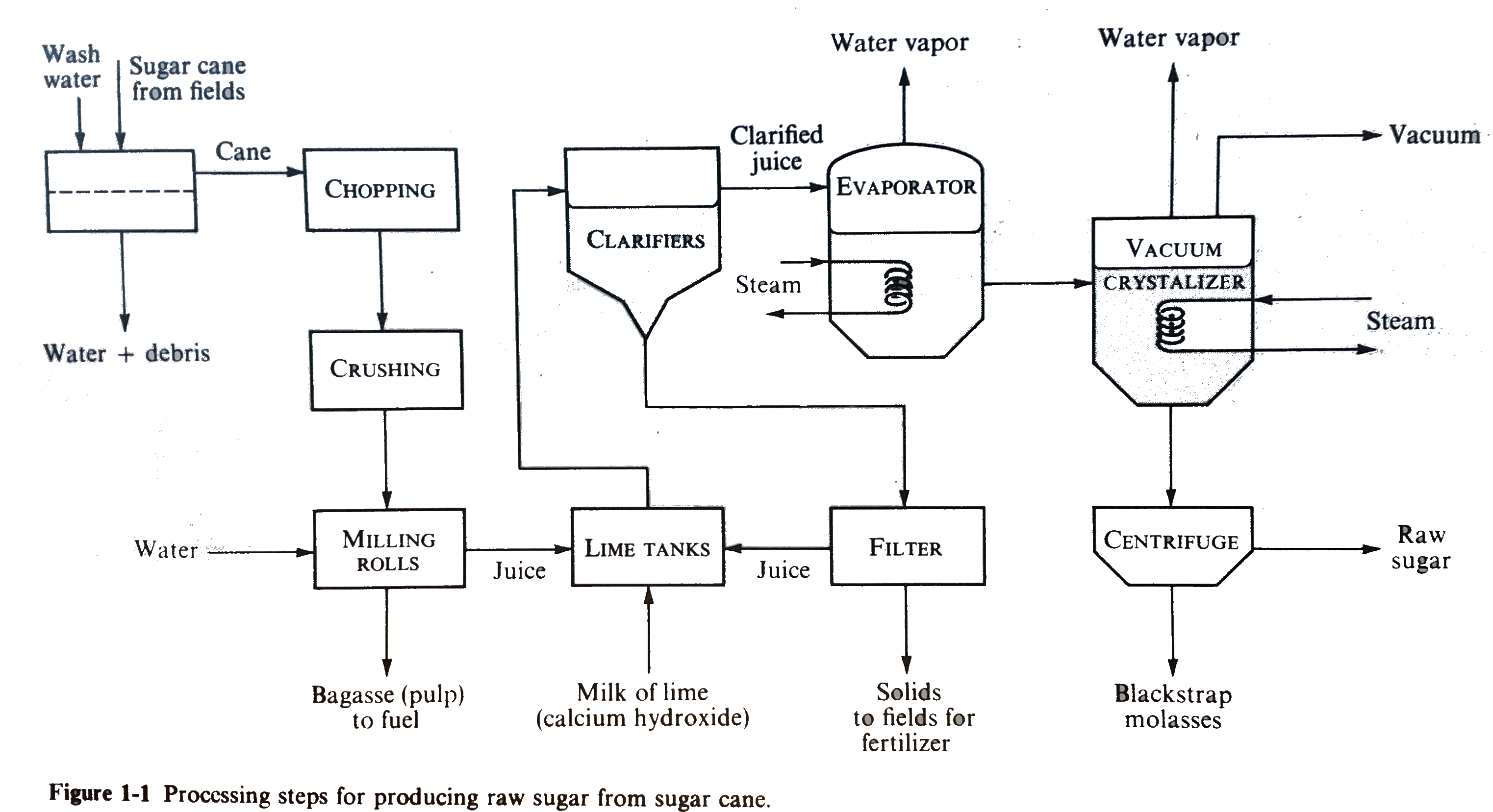

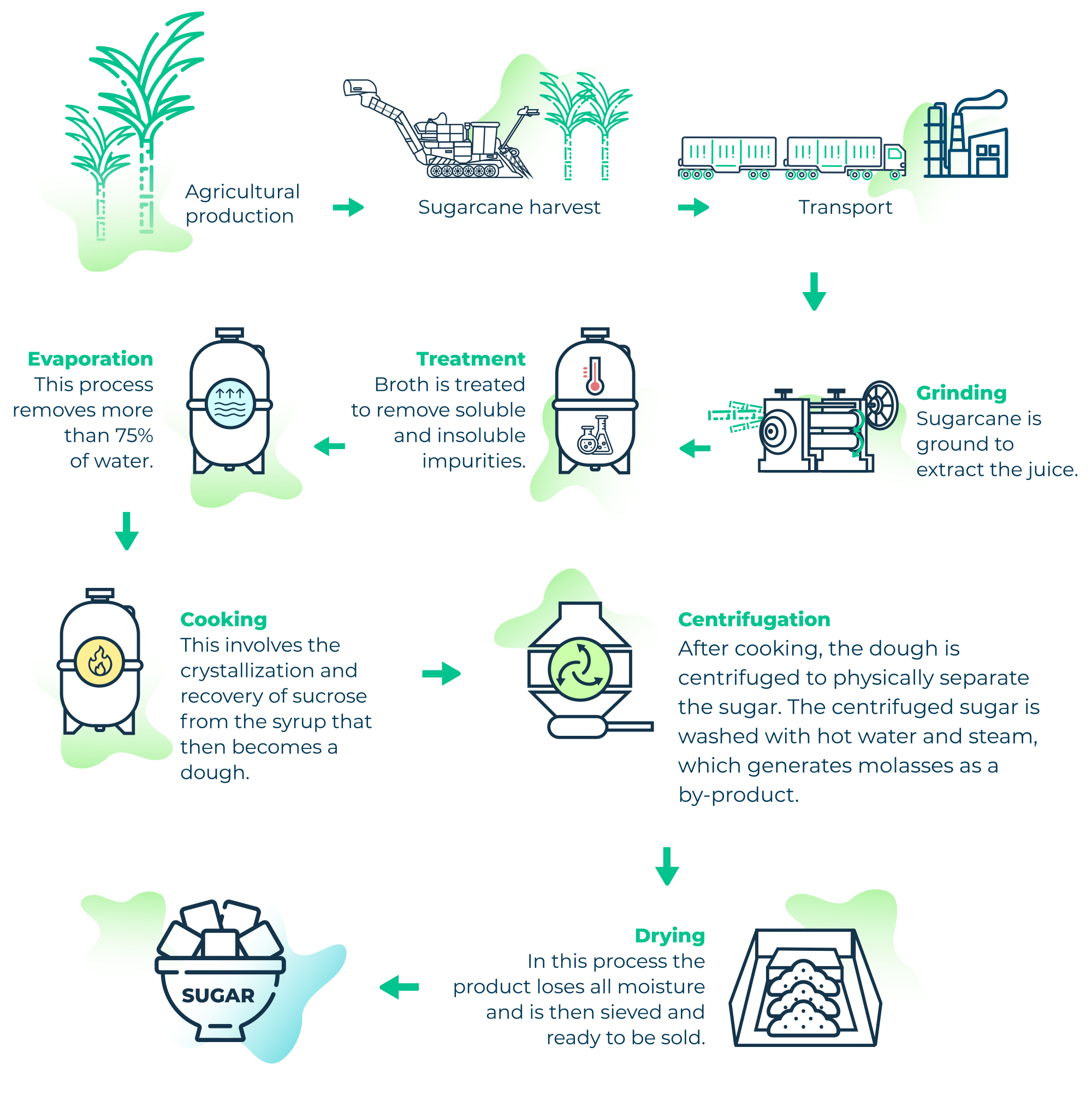

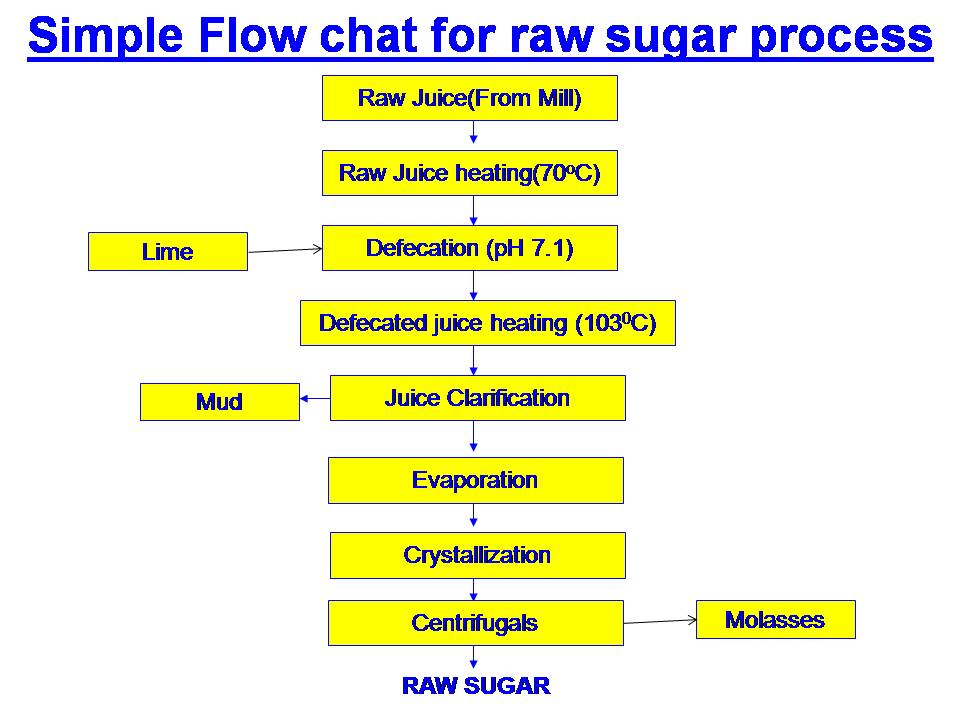

The main steps in raw sugar making process: Juice Extraction The following technologies are using the extraction of juice from sugar cane or sugar beet Milling Technology This process follows four or five stages (set of mills) for juice extraction in the milling process.

1 Existing sugar process flow diagram Download Scientific Diagram

Foam-Control Aid. Foam generation in the sugar manufacturing process results in overflow of vessel (loss of valuable products) and reduces the plant efficiency. Our defoamer formulation has superior stability at high temperature and kills the foam at low concentration level. Also, with the implementation of AI, key process variables like pH.

Sugar Industry Process Flow Diagram Cogeneration Sugarcane

A simplified process flowsheet for sugar processing. Dotted line represents the boundary of the production process. Typical mass flowrates of case-studied sugar plant are shown in.

A sugar production diagram Royalty Free Vector Image

The sugar manufacturing process in India typically begins with sugarcane cultivation on large plantations. The harvested sugarcane is then transported to a sugar mill, where it is crushed, and the juice is extracted. The juice is clarified and filtered to remove impurities, and the resulting syrup is boiled to create raw sugar.

Flow Chart Of Sugar Production From Sugarcane Chart Walls

This Processing column describes the process by which sugar is harvested and processed.. In addition to exploring the history, market, and consumption of sugar, the column will outline the steps involved in processing and production. Premium Content You've reached your monthly limit of free articles.

Sugar A Practical Guide The Rum Reader

Cane sugar processing consists of the following steps: sugar cane is crushed, the juice is heated and filtered, then sent to a series of crystallisation steps to create crystals of raw sugar, followed by centrifugation to remove any remaining juice or syrup.

[DIAGRAM] Process Flow Diagram Of Sugar Industry

sugar refineries in Guatemala had only a single milling tandem, each. Back then, the sugar mill with the largest daily milling capacity was at 12,000 T/day. From the 1997 to 2009, the sugar production had a 45 percent increase, from 1.5 million Ton to 2.2 million Ton. Figure 1. Sugar production per harvest in Guatemala

Sugar manufacturing process

Context 1. modelling techniques for various linear and linear processes are dealt with in an extraordinary way by Bequette [1]. The flow chart of the sugar industry process is shown in.

Sugar Process Flow Diagram Brown Sugar Sugarcane

Sugar Industry. Sugar can be produce from beet or from sugar cane. In India sugarcanes are used, Europe -beet is used. The mills are typically operated for 4 to 8 months after the harvesting of sugar cane. Odour nuisance near the sugar mills is a very common phenomenon. Sugar canes are cut into pieces and crushed in a series of rollers to.

Assignment 1 2014 Separation Processes 4M3

2.2.2 Cane Sugar Production A simplified process flow diagram for a typical cane sugar production plant is shown in Figure 2-1. The cane is received at the mill and prepared for extraction of the juice. At the mill, the cane is mechanically unloaded and placed in a large pile. Prior to milling, the cane is cleaned, usually with high

Infographics SugarCane

17 MAR Refined sugar making process | Flow chart and Specifications Refined Sugar Manufacturing Process In this sugar article mainly discussing about what is refined sugar, Refined sugar making process, basic steps for making refined sugar and refined sugar specifications. Mainly sugars are classified as. 1.

About us LimeX A division of British Sugar

Sugar Wastewater Aerobic Anaerobic Electrochemical Methane Hydrogen 7.1. Introduction Sugar crops are a promising alternative to food, fibers, and energy. Its consumption is steadily increasing at rate of 2.0% from 2001 to 2016. This growth remains almost stable from 2016 to 2019 with increasing health consciousness and other issues.

Sugar Industry _A Process Process Control Overview Sugar industry, Process control, Technology

Download PDF (0.61MB) Sugar beet and sugar cane processing and refining flow charts: sugar has been produced from sugar cane and sugar beet for thousands of years. After processing and refining, the end products are exceptionally pure and highly marketable and the by-products can be sold.

What is raw sugar and Raw Sugar Making Process Specification of VHP

Sweet Water Filtration Scum to Desweetening Clear liquor to Decolourisation • Affination:- Treatment of raw sugar crystals with a concentrated Light molasses to remove the film of adhering molasses. This is achieved by mixing sugar with light molasses and then centrifuging the magma with or without water washing. • Affined sugar:- Sugar which